Shirley Wenger is a professional journalist and editor who has been working in the publishing industry for more than 15 years. She is an award-winning...Read more

Pipe bursting is a leading trenchless method of exchanging underground pipes. This method involves fracturing a pipe from the inside and forcing fragments outwards while sliding a newer pipe to replace the existing pipe. This trenchless pipe bursting machine breaks the existing pipe when it pulls the bursting head through the existing pipe, splits the existing pipe and when it pulls the new pipe inside. There are several types of pipe bursting systems, which includes static pull systems, hydraulic expansion, and pneumatic system.

Natural gas pipes, water mains, and even sewer lines can be replaced without even excavating the surface under this modern pipe bursting technology. It takes into consideration, near surface utilities, pavements and other structures that might get damaged in case of a dig. Both residential and commercial customers are able to save money and time on water main renewal and sewer line repair & replacement with pipe bursting methods done by a skilled trenchless plumbing contractor.

The following are the main steps and procedures to be followed when pipe bursting:

Dig until you expose the underlying lateral pipe that is responsible for connecting personal properties to the main sewer line found along the street.

Create a connection between the main sewer and the laterals using a temporary pipe.

In order to allow the traffic to still use the street, shore excavated material and leave it covered with a steel plate. This steps might take a week or even more per block.

Dig a shaft for insertion of about twenty feet in length and 4 to 6 feet in width.

Make sure you have welded sections of the black plastic pipe a day before you carry out pipe bursting in order to make a single and block-long pipe. This long section, when left by workers at the curb overnight, can bock driveways.

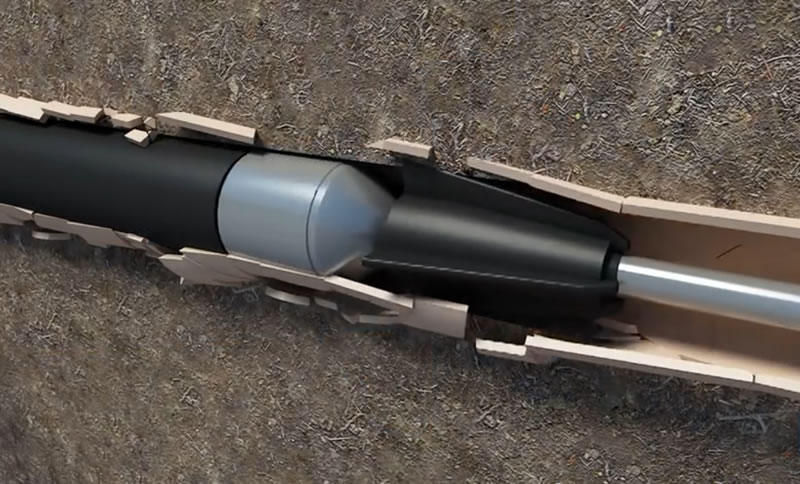

Insert a bursting head, conical in shape, into the older pipe and then place new pipe behind the bursting equipment so that it is inserted. This could block one or even more driveways and intersections for very many hours.

This bursting head then moves forward, shattering the older pipe and then then forcing fragments of the shattered pipe into the surrounding soil.

Then push or pull the newer pipe into place making sure it is right behind the bursting head. This might take a few hours for each block.

When the new main sewer has been put into place, crews should make lateral connections, temporary one sin this case, to the new pipe. This will make the sewer fully operational.

During the few days, workers should create lateral connections that are permanent, do temporary paving, and carry out backfilling of the lateral trenches

There are several equipment in the market, designed for pipe lining. However, the Perma-linerTM (PLI), considered the leading manufacturer and also supplier of equipment for trenchless pipe lining, has the best equipment for pipe lining, that are also user friendly.

Make sure you follow the above steps strictly as they have been listed. You can also find more information on pipe bursting technology through www.portlandoregon.

Shirley Wenger is a professional journalist and editor who has been working in the publishing industry for more than 15 years. She is an award-winning writer and her work has been featured in various publications, including The New York Times, The Wall Street Journal, and Time Magazine.